Brake Emissions Testing Contributions

Research Committee Partnerships

Particle Measurement Programme (PMP)

- Initial proposal to split the work into task-forces to develop test cycle, emission measurement method, and test report standard

- Interlaboratory accuracy study for repeatability and reproducibility of the WLTP cycle

- An active participant in steering team

- Application of ISO statistical methods (ISO 5725 series) for heterogeneous materials to compute standard deviations using robust methods (repeatability, sample, lab, and reproducibility), the uncertainty of repeatability and reproducibility, regressions, and statistics for stragglers and outliers (for lab average, sample, and test repetition) heat maps

- Development of open-source spreadsheet and final comprehensive report (pending publication)

- Measurement of cooling behavior for six vehicles (part of the CARB project) on proving ground per WLTP to support the GRPE 81-12 cooling method

- The lead technical writer of the GRPE 81-12

- Several presentations regarding: sampling system guidelines using EPA, EN, and ISO standards; cooling methods; experimental comparisons

- Informal Steering Team for second interlaboratory accuracy study with actual brake emissions measurements (2021)

- Proposals to PMP TF4 (with experimental results) developed jointly with OEs on how to incorporate regenerative braking and state of charge for mild hybrids, full hybrid and electric vehicles

California Air Resources Board (CARB)

- Lead laboratory for proving ground (thermal behavior only) and laboratory measurement (80+ tests) to update EMFAC model for brake emissions on six vehicles,

different materials (OE/aftermarket, NAO/LM), loading conditions, and cycles - Development of core test plan for lab testing using vehicle population, brake sizes, and replacement rate (Brake Wear Index)

- Collaborate to develop California Brake Dynamometer Cycle with real-time deceleration changes within the brake event

- Market and industry surveys for market mix and product replacement rates

California Department of Transportation (CALTRANS)

- Equivalent project to CARB but for commercial vehicles; seven driving cycles, ~40 tests

Industry

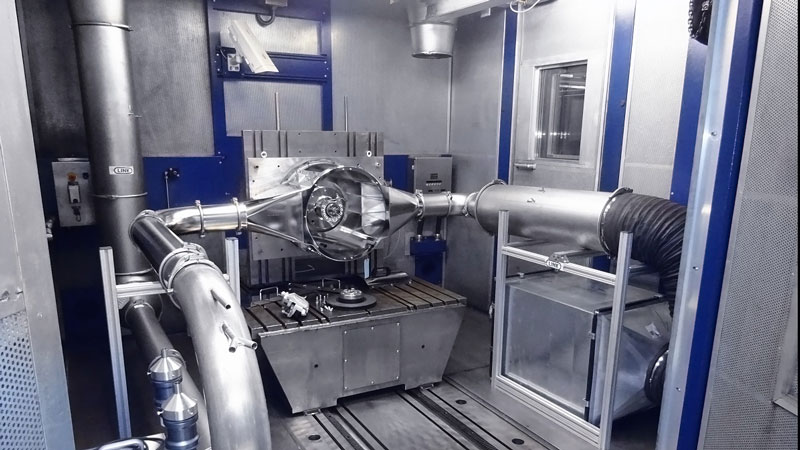

- First laboratory accredited with ISO 17025 for brake emissions testing service for passenger cars, light trucks, and commercial vehicles

- ProLINK software to replicate WLTP-Brake, WLTP-Exhaust, or other drive cycles with real-time correction for parasitic losses

- ProLINK RegenSim 2.0 simulation to conduct emission tests for HEV or BEV platforms, with State of Charge scaling under development

- Implementation of SAE and GTR15 metrics for speed violations and speed error

- Open-source macro to estimate transport losses using aerosol engineering, combining several tools and methods (SAE; EPA; CDC, Max Plank Institute; Kulkarni,

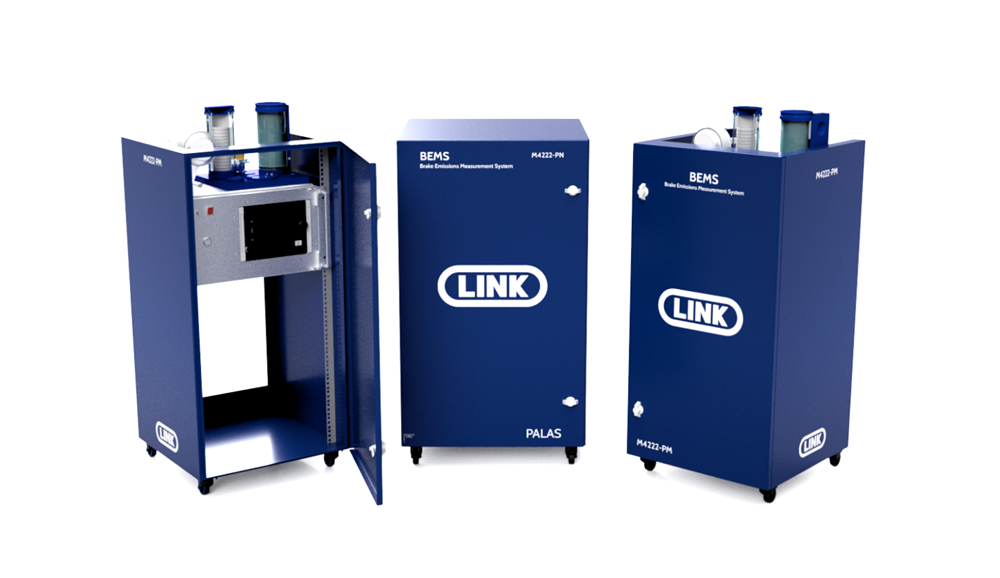

Baron, and Willeke) - Development of fully-integrated sampling tunnel and instrumentation cluster for PN10, PM2.5, PM10, particle size distribution (6nm to 20 µm), and time-based

particulate mass (45 nm to 2.5 µm) - Self-contained weighing room (Dearborn) to weigh and report PM gravimetric filters per 40 CFR Part 1065 (CARB also follows this standard). Weighing room operation verified by EPA through an interlab study. implementation of ISO 17025-accredited weighing process for LINK Europe

- Ability to integrate data from emissions measurement devices and sensors from multiple vendors, including signals, warnings, quality controls, and direct operation of pumps as part of the test cycle

- Integration of electronic data output from brake emissions measurements for particle number, dilution, background emissions, and time-based particle mass with dynamometer native measurements (speed, torque, pressure, temperatures, etc.)

- Implementation of brake emissions measurements at two LINK facilities (Dearborn and Limburg) to support corporate projects

- First extensive DOE with high-fidelity CFD simulation including particle inception and metrics for particle size distribution

Publications

- Agudelo, Carlos, Ravi Teja Vedula, and Tyler Odom. Estimation of Transport Efficiency for Brake Emissions Using Inertia Dynamometer Testing. No. 2018-01-1886. SAE Technical Paper, 2018.

- Agudelo, Carlos, Ravi Teja Vedula, Jesse Capecelatro, and Qingquan Wang. Design of Experiments for Effects and Interactions during Brake Emissions Testing Using HighFidelity Computational Fluid Dynamics. No. 2019-01 2139. SAE Technical Paper, 2019.

- Agudelo, Carlos, Ravi Teja Vedula, Sonya Collier, and Alan Stanard. Brake Particulate Matter Emissions Measurements for Six Light-Duty Vehicles Using Inertia Dynamometer Testing. No. 2020-01-1637. SAE Journal, 2020.

- EB 2019 – Thermal and braking regimes during proving ground measurements using WLTP-Brake cycle for brake emissions measurements

- Grigoratos, Theodoros, Carlos Agudelo, Jaroslaw Grochowicz, Sebastian Gramstat, Matt Robere, Guido Perricone, Agusti Sin et al. “Statistical Assessment and Temperature Study from the Interlaboratory Application of the WLTP–Brake Cycle.” Atmosphere 11, no. 12 (2020): 1309.

- EB 2021 – Experimental valid

Inventory of Global Laboratory Projects for Brake Emissions Measurements

Over 10 projects for environmental agencies, vehicle manufacturers, and brake systems suppliers, including:

- Statistical assessment and temperature study from the ` interlaboratory application of the WLTP–Brake cycle

- Exploratory Brake Emissions Benchmarking – a Design of Experiments

- Update emission factors for light-duty vehicles-in-operation in California

- Update emission factors for heavy-duty vehicles-in-operation in California

- Update emission factors for most common electric vehicle-in-operation in California

- Elemental and organic carbon analysis of brake-generated particulates

- Measure brake emissions for different friction materials under PMP WLTP-Brake test procedure

- Measure brake emissions under PMP WLTP-Brake test procedure with and without regenerative braking

- Benchmarking emissions for different friction materials of selected vehicle platforms

- Comparison of old and new Drum design

- OE vs prototype pads and discs. Using standard performance and wear tests

- Survey different types of discs used on high-performance vehicles

- EB 2021 – Experimental validation of the PMP air cooling adjustment for brake emissions measurements

LINK Brake Emissions Testing Equipment

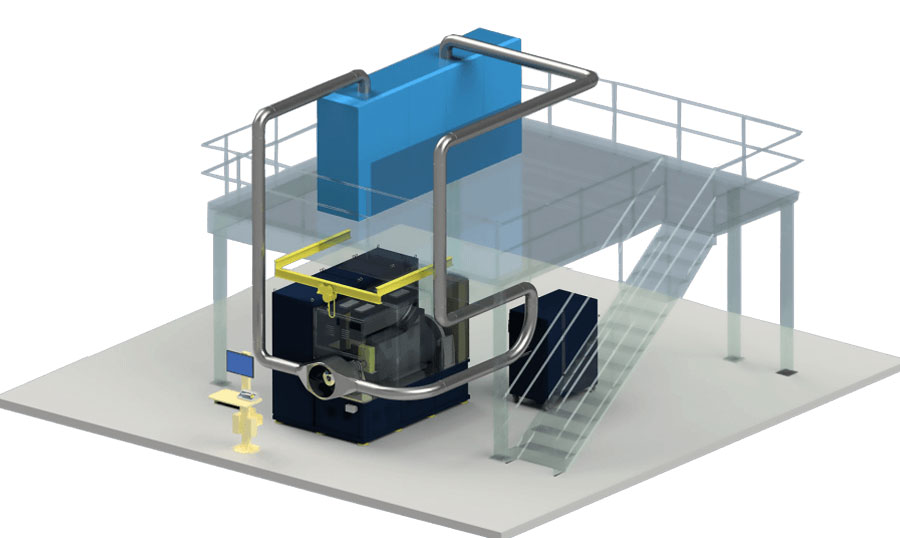

Emissions Pro & Pro+ Dynamometers

Model 3900 NVH Brake Emissions Dynamometer