Testing

Smarter Laboratory & Vehicle Testing Solutions

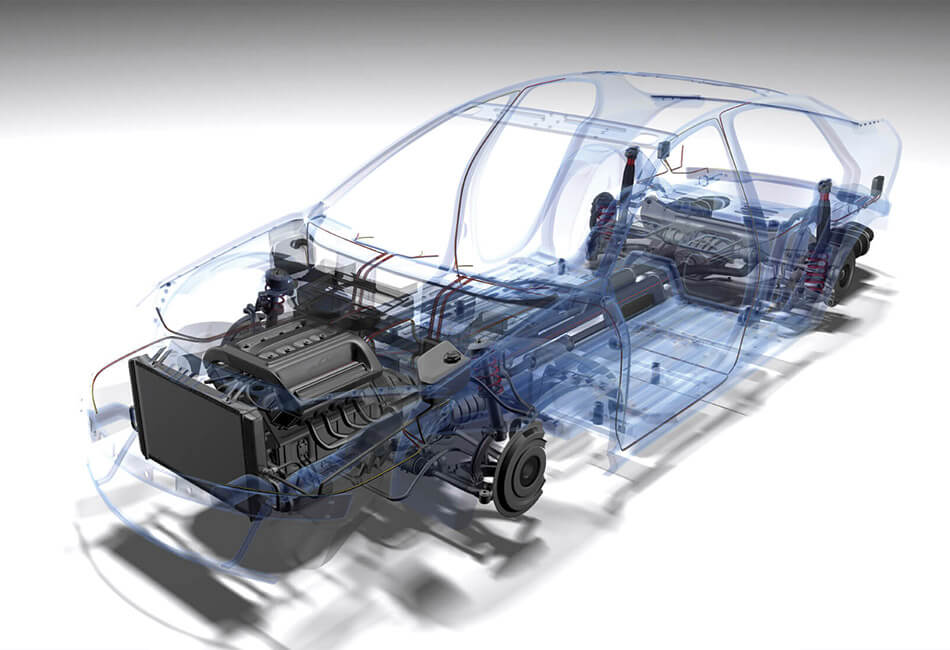

Whether you are testing for structural integrity, striving to meet new certification standards, or assessing performance capabilities, you need data that is accurate, reliable, technical, and timely. With over 80 years of testing experience and presence on four continents, you can draw on LINK’s deep expertise to find a solution to meet your precise needs.

You can test in our labs, buy your own system, or mix and match to fine-tune a solution just for you. You can rely on LINK staff members who are experts at managing every facet of a testing laboratory. We even provide scalable staffing and asset management, meaning you can install your test equipment at one of our laboratories, have LINK manage or maintain your equipment or laboratory, or perform your testing at one of our global facilities.

The LINK team is here to serve, providing efficient custom solutions. How can we help you? View our testing brochure.

Testing Applications

Our capabilities are constantly growing as we incorporate emerging technologies and testing methodologies, such as EV and ADAS. We offer remarkable flexibility, comprehensive knowledge and actionable analysis as a vertically integrated testing provider unlike any other. Get a solution on demand – whatever the challenge.

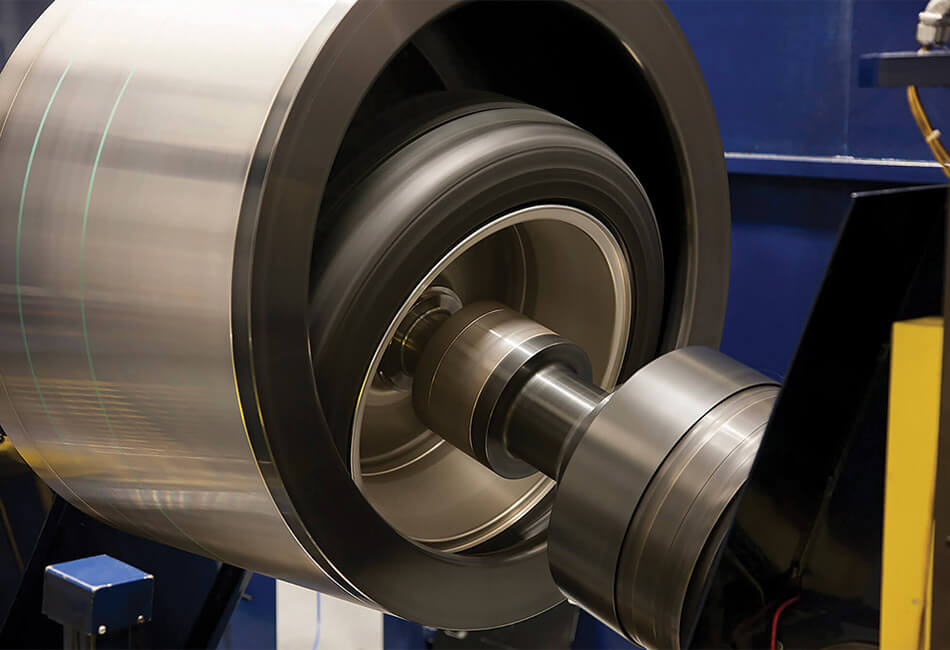

TIRES

WHEELS

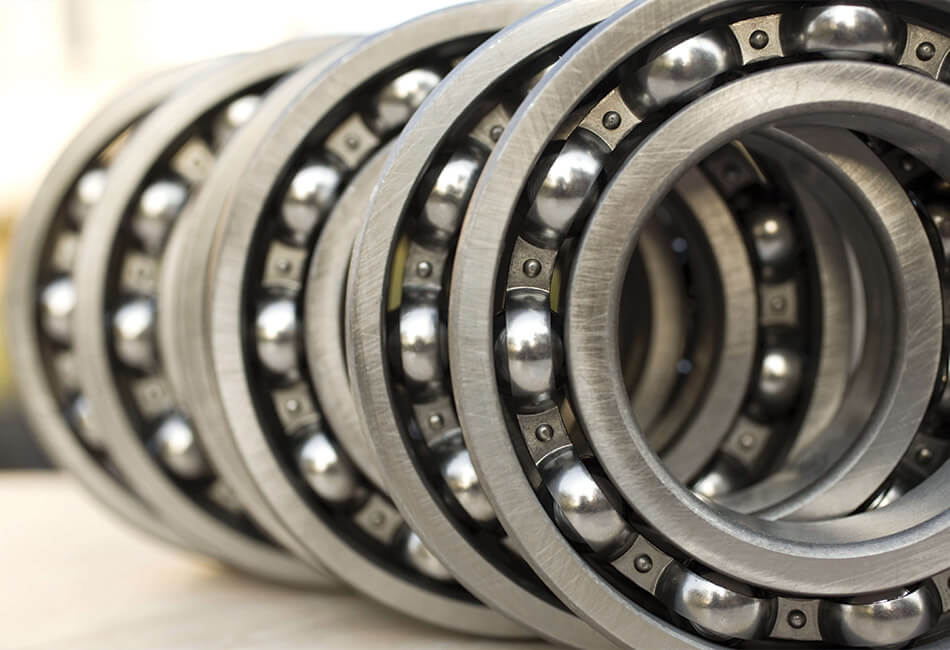

hubs/bearings

brakes

Chassis Components

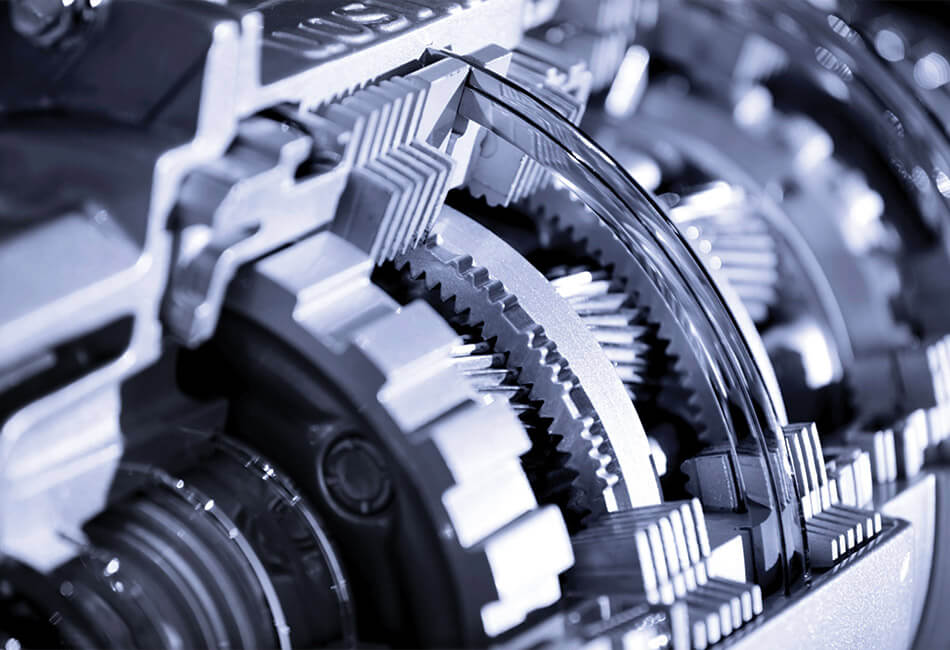

driveline

steering

adas

electric Motors

Chassis Components

Test Types

We’re driven to provide you with customized solutions and the understanding that powers winning decisions. You aren’t just looking for pretty charts, you are looking for actionable results. When testing with LINK, you have access to the smartest testing solutions in the industry. Take a look.

Performance

Performance testing and evaluation is one of the core activities of any automotive development program, ranging from quality control of raw materials, to compliance testing as part of the entire vehicle. LINK’s expertise and capability of providing testing systems and testing services have been the backbone of our success in the testing industry. Whether you are assessing behavior as a function of speed, pressure, temperature, or environmental conditioning; assessing the ability of a tire to withstand the FMVSS plunging force; verifying the threshold pressure of a brake caliper; or measuring accurately the vehicle’s stability control system performance on the proving grounds, LINK can offer a solution.

Durability

Besides performing or meeting performance requirements, automotive components and systems need to last with predictable behavior and safety. More than ever, the vehicle is expected to operate in multiple regions of the world with minimal localization efforts. Wear, structural integrity, product life, and assurance of product life according to engineering and market expectations require stringent and lengthy test programs. LINK has the ability to support laboratory testing and in-vehicle evaluations with high-end data acquisition systems, coupled with a wide network of testing facilities around the world. Wear rates and life expectancy evaluations; changes in behavior and performance as a function of driven distance; and sensitivity to environmental effects are some of the areas where LINK test systems or testing services can support your reliability and durability evaluation.

Vehicle Dynamics

NVH

Issues related to noise, vibration, and harshness (NVH) is still one of the most frequent reasons for come-backs, warranties, and customers switching to a competitor. In many areas noise and vibration is still elusive for computer simulation. The actual interactions of multiple components, product features, and system response to transient energy input or product conditions are quite difficult to assess without testing.

Whether a product is quiet during winter driving conditions, at high temperatures during a mountain descent, or when driving down a parking structure ramp at constant speed, is a matter of using reliable and well-engineered testing systems and testing services. If a product remains quiet after driving for extended periods, or if it develops severe pedal pulsation due to rotor thickness variation, is a matter of working with a testing partner like LINK who provides cost-effective testing programs with dynamometers and testing centers around the globe. Using standard tests like the SAE J2521 or city circuits, or a chassis dynamometer with cold and humid environments to fingerprint the noise characteristics of your product, LINK’s testing capabilities can help you improve your product and differentiate you from your competitors.

Structural & Fatigue Testing

Structural and fatigue testing of components are critical safety issues which can cause severe or irreparable damages, and can put a significant dent on your product reliability and reputation. When critical questions related to product reliability, structural integrity, and compliance to regulations emerge is when and where LINK’s test systems and test engineers can be put to the test. Our experience and engineering capabilities enables you and your product to demonstrate compliance, validate product designs, compare to your competitor, and give the assurance to your customers that your product design and performance meets and exceeds their expectation and your specification.

Chemical

When the friction material industry was faced with the challenge to meet the deadline to comply with the new rules on copper and heavy metals in the states of Washington and California, they came to LINK. Even though chemical analysis was a new endeavor for us, the business challenge and the need to meet the most stringent technical requirements of a new regulation were not. Following the applicable SAE standards (like the SAE J2975), LINK was able to provide chemical evaluation for friction materials suppliers from around the world, to secure ISO 17025 accreditation in time for manufacturers to meet the deadlines on the Better Brake Rules, and to provide timely reports so the manufacturer could continue production and shipments without interruptions.

Am I well below the 5% target for copper that my customer is requesting? May I advertise and label my formula as copper-free? Am I confident my batch-to-batch and plant-to-plant variation are under control for hexavalent chromium and cadmium? May I use the same manufacturing equipment to produce asbestos-free drum linings? These and many other questions from your R&D team, your customers, and your sales staff can be answered accurately, reliably, technically, and timely when you reach out to the LINK team.

Certification/Type Approval

Since LINK works with the main type approval authorities, has a designation as a technical service by RDW from the Netherlands, and has been conducting testing to the ECE rules since the early 2000s, we are your partner of choice in China, the U.S., Brazil, or Europe to pursue type approval. If your needs are related to meeting FMVSS regulations for drive-by noise, electronic stability control, tire performance, timing requirements for air supply systems on tractor/trailers combinations, or complying with the reduced stopping distance for commercial vehicles, LINK is your testing service provider of choice.

Measurement (Metrology)

Whether you are assessing wear and dust in city traffic, performance on a test track, durability of wheel-end components, DTV induced by highway driving, cold judder due to brake drag, hot judder from transient thermal distortion of the rotor, cold noise in Manitoba, actual pressure levels on military jet fighter brakes, or completing other measurements, LINK can help you. LINK is here to help your team devise a test plan, get the logistics in place, execute the testing, and report the results in the format of your choosing so you can understand with minimal questions in order to make data-driven decisions for your product and your business.

Testing Services

United States

EAST LIBERTY, OH +1 937.666.5006

DEARBORN, MI +1 313.625.4000

OTTAWA LAKE, MI +1 734.387.1000

WITTMANN, AZ +1 623.505.9250

CARSON, CA +1 623.505.9250

DEARBORN, MI +1 313.625.4000

DETROIT, MI +1 313.625.4000

International

LIMBURG, GERMANY +49 6431.90888.10

SOROCABA, BRAZIL +55 15.3416.0601

MOJACAR, SPAIN +49 6431.90888.10

MAGENTA, ITALY +39 02.99247065

HUANGSHAN, CHINA +86 21.5916.5656

SHANGHAI, CHINA +86 21.5916.5656

SEOUL, KOREA +82 31.761.8288