Equipment

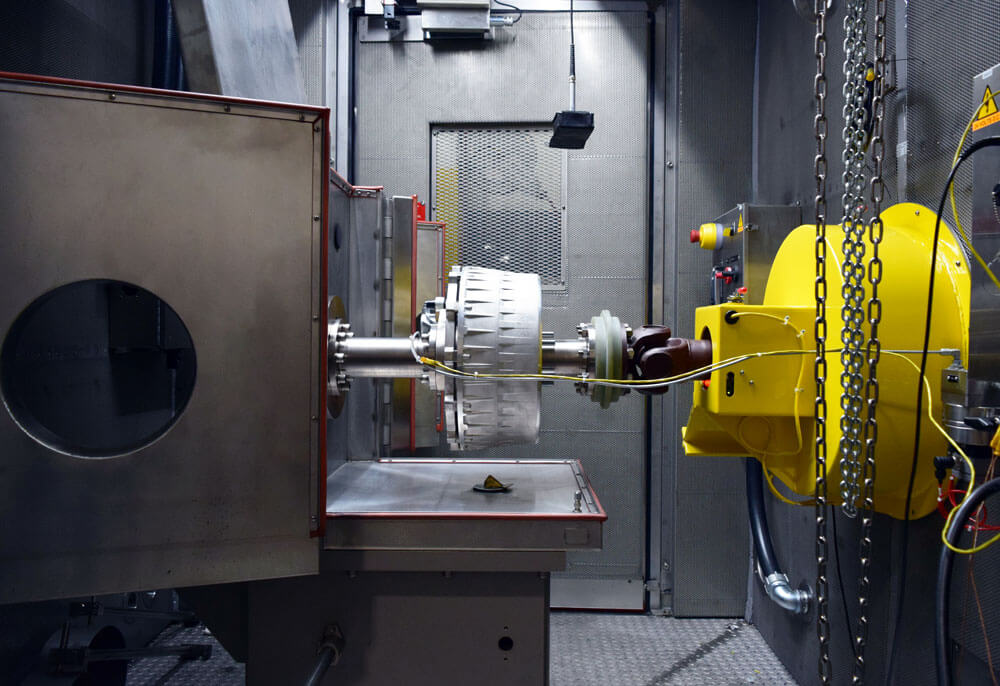

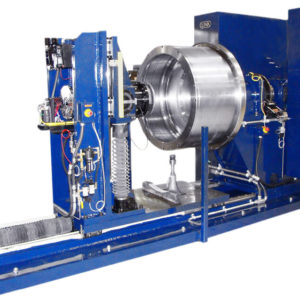

M6642 Hub Motor and NVH Test System

Product Overview:

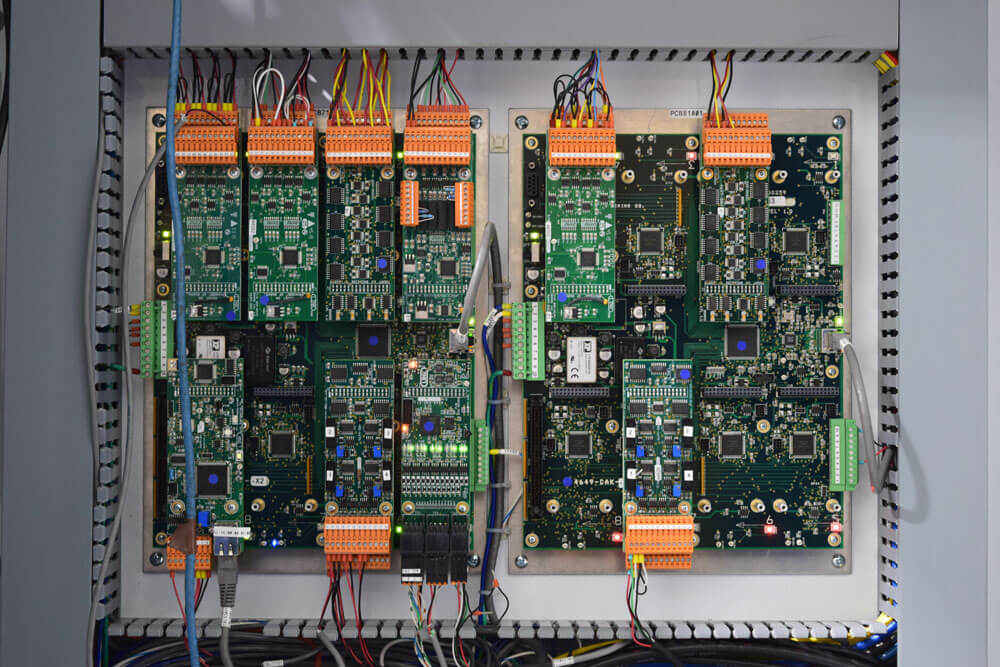

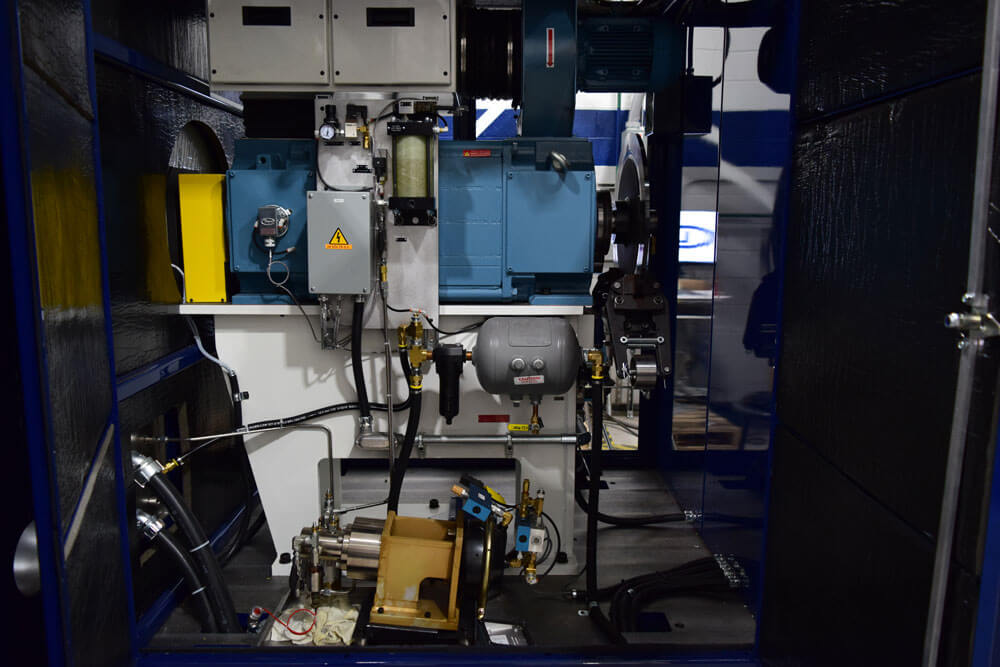

The Model 6642 can perform extensive motor characterization, run full hydraulic friction brake tests within inertia simulation capability, and operate in combined or blended modes between the two subsystems. It functions in both drive and brake modes seamlessly, with the control system having the ability to augment the desired torque/speed target automatically by engaging or actuating each subsystem through staged open and closed-loop control. The capabilities presented in our state-of-the art Hub Motor Test System can be combined with LINK’s industry-leading software, offering the quickest and most complete way to move from vehicle testing to the laboratory.

Key Features:

- AC Motor Dynamometer

- High Accuracy Precision Torque Sensor with Telemetry

- “Free Field” Environmental Chamber

- Full Integration with Power or Motor Analyzer

- 1 to 800V DC Battery Simulator

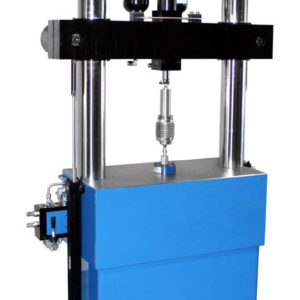

- Precision Electric Hydraulic Brake Apply System

- Static Rotor Lock/E-Brake

Product Capabilities:

- Typical Motor Performance Test

- NVH Motor Test

- Waterfall FFT

- Octave, 1/3 Octave, Loudness

- Sound Power

- NVH Friction Brake Test (SAE J2521)

- Multiple Operation Modes

- Motor Only in Drive/Brake Modes

- Motor + Hydraulic Friction Brake

- Blended

- Combined

- Typical Foundation Brake Testing

- Broad Range of Internal Test Motor Fluid Cooling/Heating (-40 to +90c)

- Broad Range of Environmental Conditioning (-40 to +60c) In Primary Chamber

- Optional Secondary Sub Chamber to Speed Up Heat/Cool Environmental Cycles (-40 to +90c)

- Flexible Tailstock Motor/Brake/Suspension Mounting System

- Motor Only

- Motor/Brake/Rigid Knuckle Fixture

- Motor/Brake/Full Suspension

- Low Torque and Speed Ripple Dynamometer Motor