Equipment

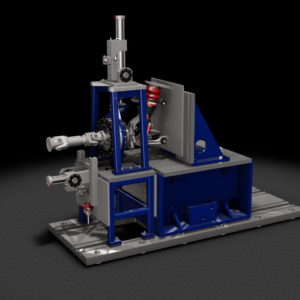

Model 200/600 Chase Friction Material Test Machine

Overview

The Chase Friction Material Test Machine is designed and engineered to evaluate the frictional characteristics of materials used in braking systems in accordance with the SAE J661 test procedure. The machine may be effectively utilized for quality control, research and development, or certification type applications, with highly repeatable results.

The operation is based upon approximately (27 mm, 1.06 inch) sample of material which is contoured to rub against the interior of a simulated brake drum. By controlling either the normal load or the friction force while monitoring the other parameter under various thermal, speed, and load conditions, an assessment of the material’s frictional properties may be made. Rubbing speed is controlled by a variable speed drive, load is controlled by a closed-loop servo system, and the temperature of the test drum is controlled by resistance heaters and a forced-air cooling system.

Key Benefits

- Fully automatic controls for autonomous operation

- Integrated drive cabinet to streamline installation

- Friction characterization

Key Features

- ProLINK Control and Data Acquisition

- Manual or automatic operation

- Calibration assembly

- Sample and drum grinding unit

- Servo control load apply

- Automatic report generation (J661)

Test Procedures

- SAE J661