Link Engineering Company’s Model 4000 (V-Max) Data Acquisition system offers OEM’s and suppliers a greater range of precision, modularity and user friendliness in vehicle data collection. LINK designed the V-Max’s chassis with interlocking and easily interchangeable modules, making the V-Max a versatile, portable, and completely modular system. Recent expansions to the V-Max’s capabilities will make it easy for users to record video during testing.

While video recording isn’t new for LINK laboratory testing equipment or our ProLINK software, the new V-Max packages take advantage of ProLINK’s capability to document video and testing data side by side, and introduces this capability to vehicle testing. The new Model 4067 – DVC Camera system provides flexible, modular means of recording video in harsh conditions and with a wide dynamic range. The system comes in two versions, a normal lens camera for detailed shots and a fisheye lens camera for dynamic shots taken in strategic locations such as a vehicle’s dash.

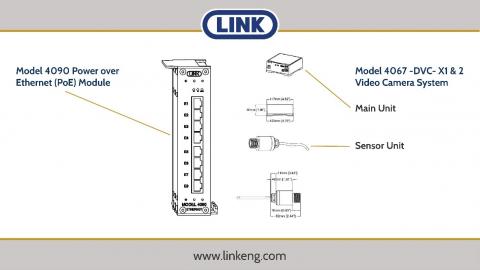

Power for the main unit can be supplied via the new Model 4090 Power over Ethernet (PoE) Module or from a user supplied power supply of 8 Vdc to 28 Vdc. The new PoE module has other applications outside of powering the new camera system, as it can power other ethernet based systems such as ethernet vehicle transducers. The combination of PoE and the camera system will increase the customization possibilities of the already versatile V-Max system. As new testing needs arise, and autonomous vehicle testing becomes more and more prevalent, the camera system can prove to be a vital tool to document video during an unusual or isolated incident, especially when there is no person operating the vehicle.