Equipment

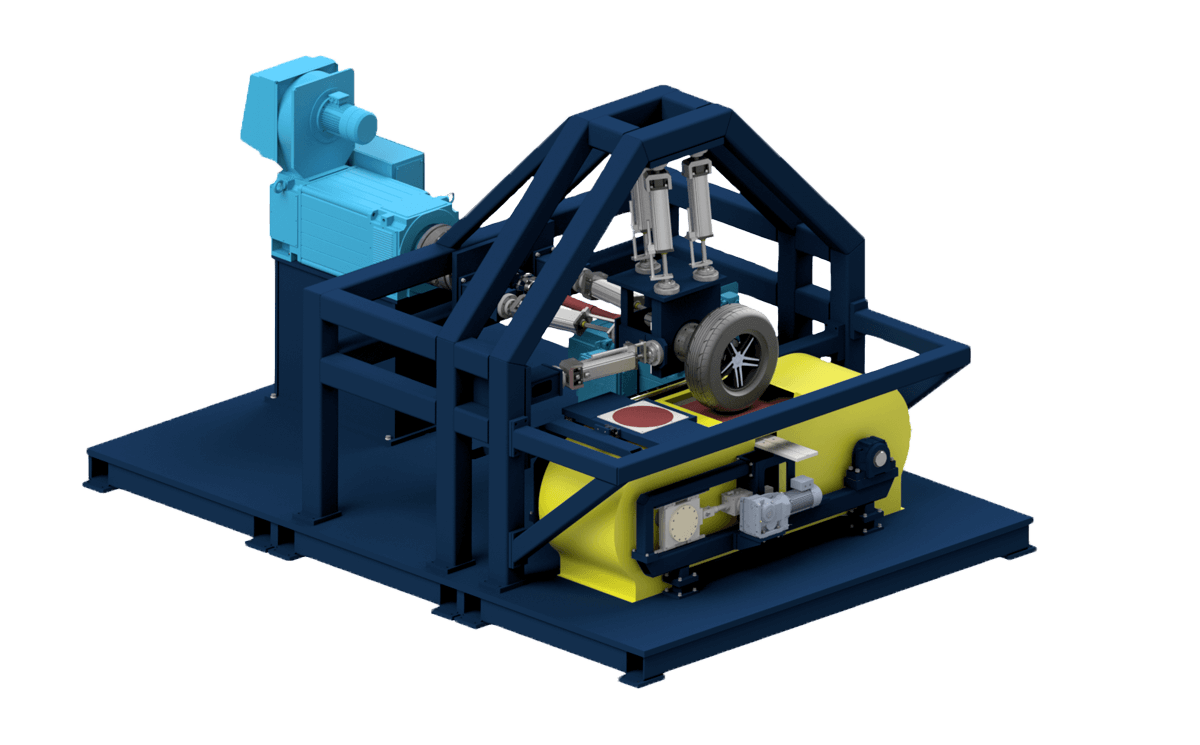

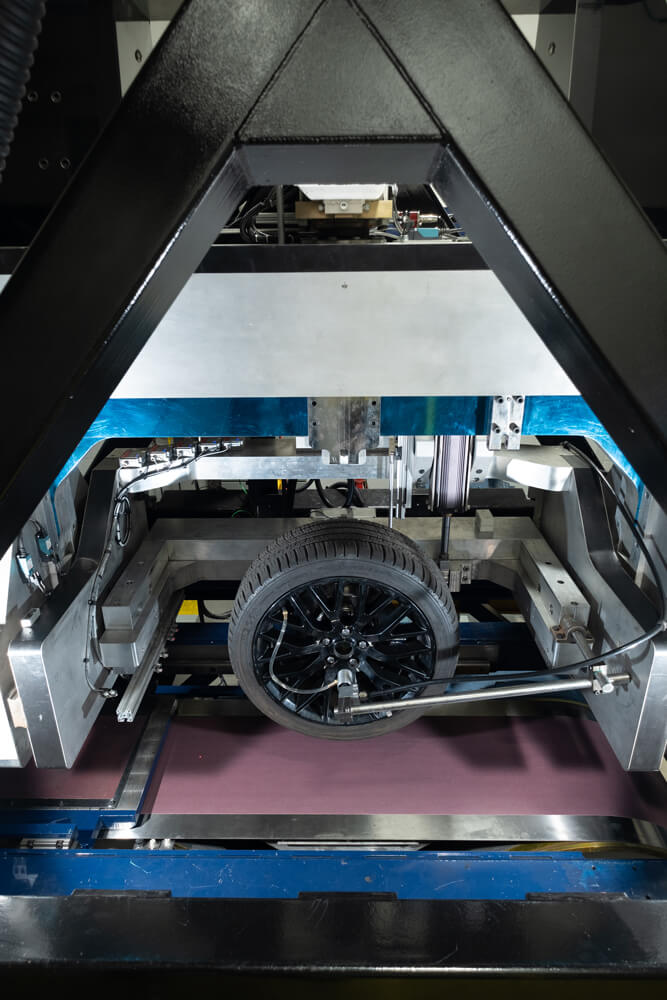

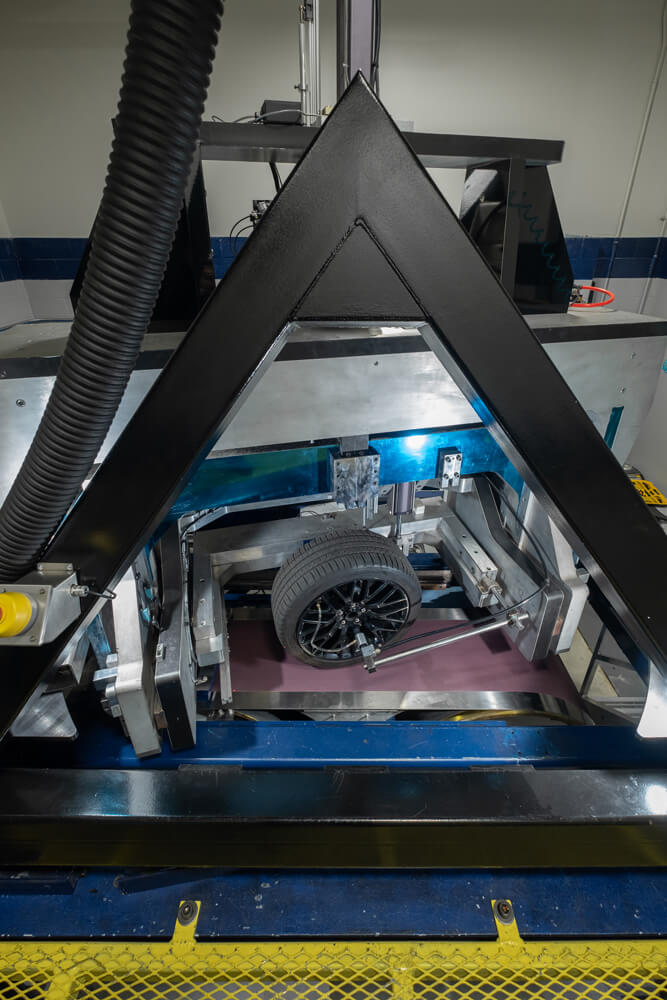

321 Flat Belt Machine

Overview

LINK not only designs and develops test equipment, it also operates testing labs 24/7 and employs some of the industry’s most notable experts, so that its customers benefit from innovation based on experience.

The 321 Flat Belt Machine, on a rolling road platform, expands LINK’s testing capabilities. We can now test virtually the entire breadth of components on the automobile, from driveshafts to hubs, bearings to brakes, and wheels to tires.

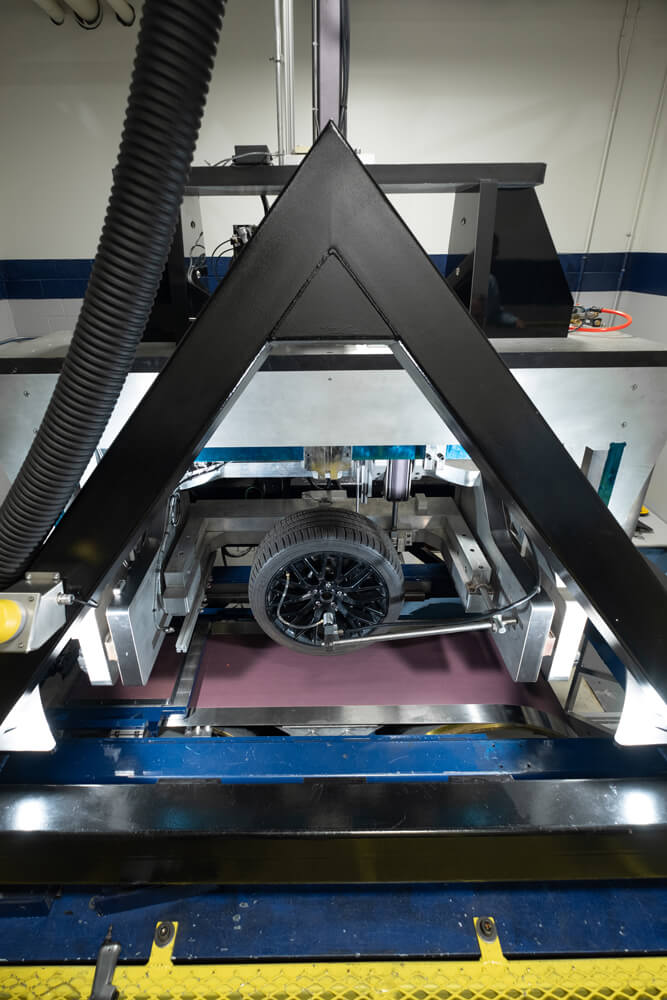

The 321 Flat Belt Machine can perform parking forces, a one-of-a-kind capability used to accurately determine forces encountered by the tire and steering components during parking or similar events. This capability was designed to provide the customer a tool for accurately predicting the forces applied to the tire, suspension and steering mechanisms during the most extreme conditions of operation.

Key Features

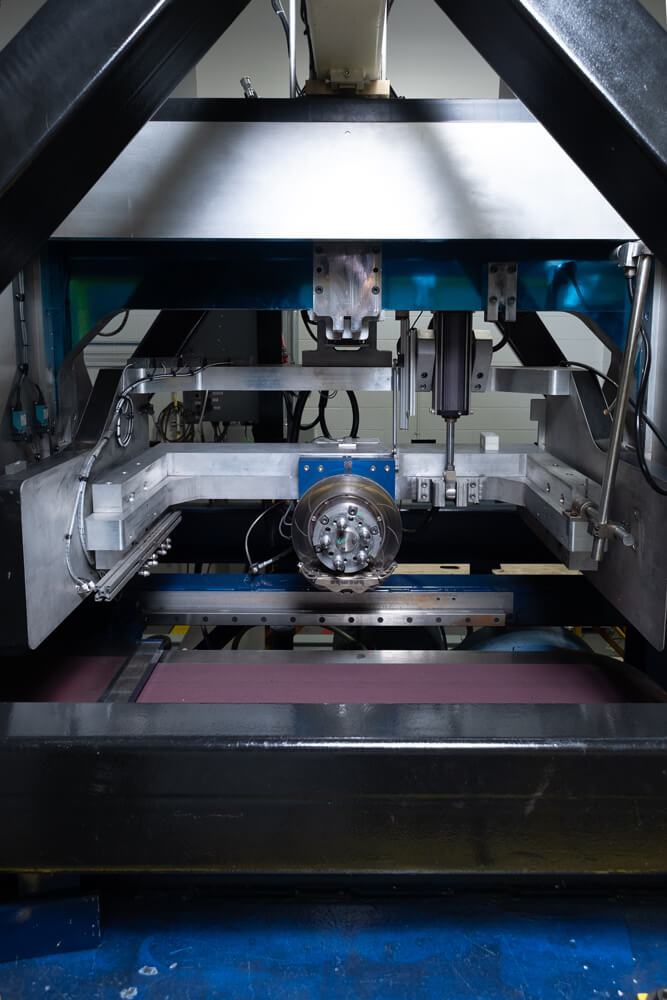

- Force and Moment Measurements

- Turn-key Testing Services and Tire Model Generation, including for example:

- Magic Formula 5.1, 5.2, 6.1, 6.2 model generation

- MF-Swift models

- FTire Models

- Static Stiffnesses

- Tire surface temperatures

- Rolling Radius

- Parking Forces

- Dynamic scrub radius

- Dynamic inclination angle

- Virtual, dynamic kingpin orientation

- Braked or Free-Rolling

- Emulation of complex suspension configurations, such as double ball-joint suspension movement and dynamic kingpin inclination angles

Applications

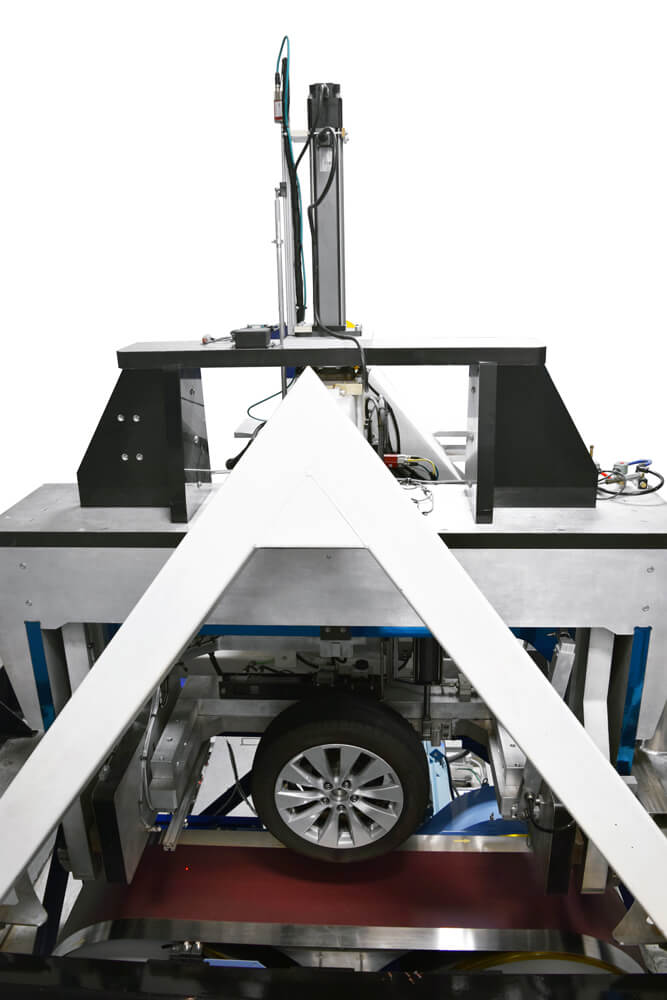

The 321 Flat Belt Machine achieves accurate assessment of forces and moments applied to the tire under realistic operating conditions, but without the limitations found on many conventional force and moment machines. So not only can LINK’s 321 Flat Belt Machine conduct standard force and moment tests, it can also replicate the motion of the tire caused by suspension geometries, with the following capabilities:

- Ability to offset the tire from the rotation (SAE-Z) axis to replicate a scrub radius

- Ability to replicate kingpin inclination angles and resulting motions during a steering event

- Braked and free-rolling conditions

Force generation is complex when the tire experiences both rotations and sliding caused by scrub radii and changing inclination angles. Modeling these forces is even further complicated when the kingpin inclination angle shifts the contact patch from one sidewall to the other during the steering event.

The 321 Flat Belt Machine provides the unique capability of testing the exact conditions the tire will see, long before a prototype vehicle is developed. This gives the automotive customer insight to optimally size power steering pumps and related equipment early in the design cycle.