Equipment

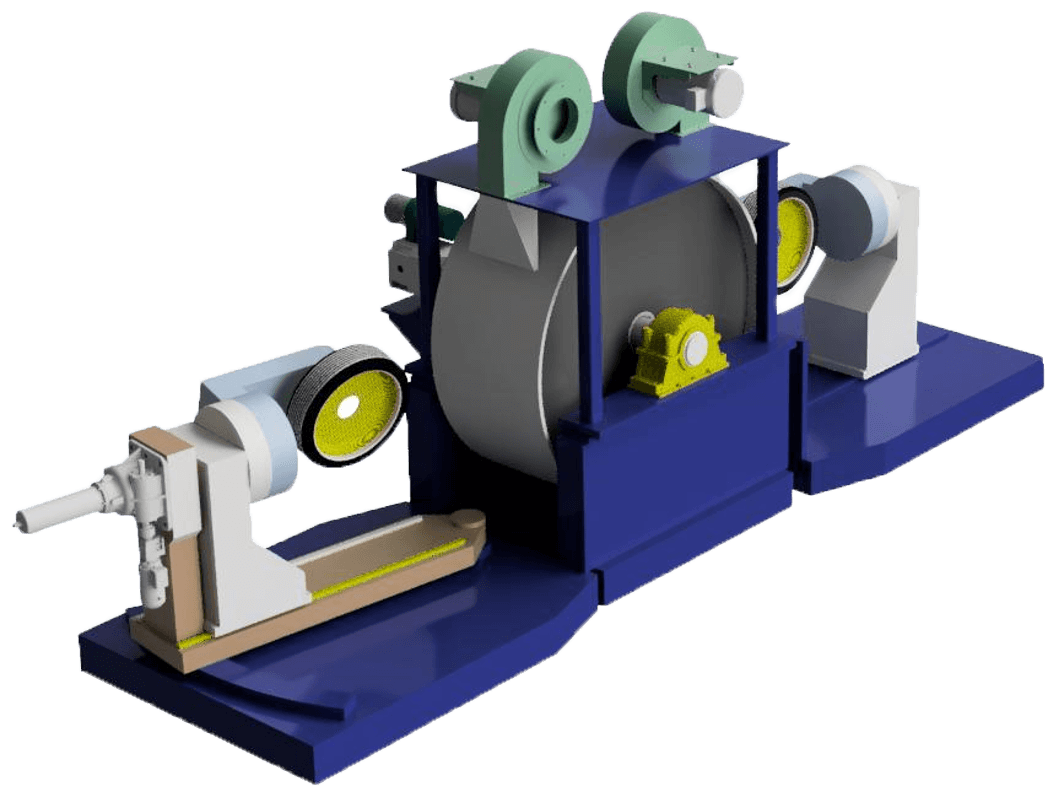

All-in-One Rolling Drum Machine

Overview

Rolling drum machines are used for a large variety of standard tire testing procedures. The All-In-One Drum Machine is designed as the perfect middle-ground, offering reliable and accurate data for any type of drum test, all on one machine. The machine provides many benefits, including substantially lower capital costs, a smaller laboratory footprint, and reduced manpower. The user can optimize operation of the machine, adding additional capabilities as the business grows organically. This ensures optimal uptime and utilization, providing an unparalleled ROI.

Key Features

The All-In-One Drum Machine utilizes a precision drum roadway and two purpose-built stations.

Station 1 includes a strain gauge head with dynamic slip and camber degrees of freedom. This station is therefore ideal for limited force and moment tests, wear tests, and durability.

Station 2 utilizes a piezoelectric head mounted on an exceptionally stiff, lockable tailstock with zero slip angle and zero camber angle. This station is designed to have a high natural frequency such that it is ideal for cleat tests and high-speed uniformity tests. In addition, this station is appropriate for measuring rolling resistance and, with the optional semi-anechoic chamber, NVH (noise, vibration, and harshness) profiles.

- Station 1: Strain-Gauge

- Controlled Z-axis, Camber, & Steer

- Ideal for Rolling Resistance, Wear, Durability, and Playback tests

- Station 2: Piezoelectric

- Controlled Z-axis

- Ideal for High-Speed Uniformity and Cleat testing

- Optional semi-anechoic chamber for NVH testing

- Changeable surface shell

Applications

As its name suggests, the All-In-One Drum Machine can do it all. The two-meter diameter drum reaches the perfect compromise between cyclic tests, such as cleat testing, and tests that desire a flat footprint, such as wear testing. The Piezoelectric station has higher stiffness, necessary for sensitive tests such as high-speed uniformity. The Strain-Gauge station allows additional control for camber and steer, necessary for drive file playback and force and moment testing.

Some of the common types of tests this machine can perform are listed below:

- Rolling Resistance

- Noise, Vibration and Harshness, with optional anechoic chamber

High Speed Uniformity - Cleat Testing – necessary for the creation of tire models such as FTire, MF Swift, etc.

- Durability

- Wear simulation, including convoy playback capabilities