Equipment

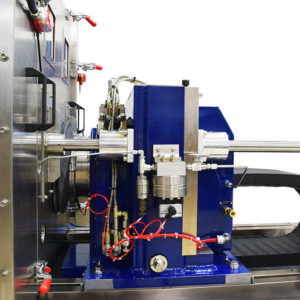

Model 4222 Brake Emissions Particle Measuring System

Product Overview

LINK’s Model 4222 Brake Emissions Particle Measuring System is designed to accurately measure and report particle mass (PM10 and PM2.5) and particle number (Solid and Total). The Model 4222 system enables the operator to automate filter changing (via filter tracking with an RFID) and have the system provide real-time monitoring and operation. Additional instruments can measure particle size distribution and real-time mass measurement.

LINK’s design meets the GRPE-87-40 testing procedure and can support future R&D to understand better the factors influencing your emissions. Integrating the Model 4222 system builds on our expertise in integrating measurement systems as part of standard dynamometer systems (e.g., noise and vibration analyzers, thermal imaging, capacitive sensors, and specialized torque measurement systems).

- Key Features

The LINK Model 4222 Brake Emissions Particle Measuring System Provides:

- Self-contained, pre-calibrated, and fully integrated with our ProLINK controls and data acquisition systems

- The seamless testing process, from background checks to automated PM filter changes (to avoid downtime between cycles or during off-shift testing), to real-time monitoring and quality controls

- Ease of transport and connection (or disconnection for non-permanent installations) to the dyno controls and the sampling train—simplifying calibration and maintenance