Equipment

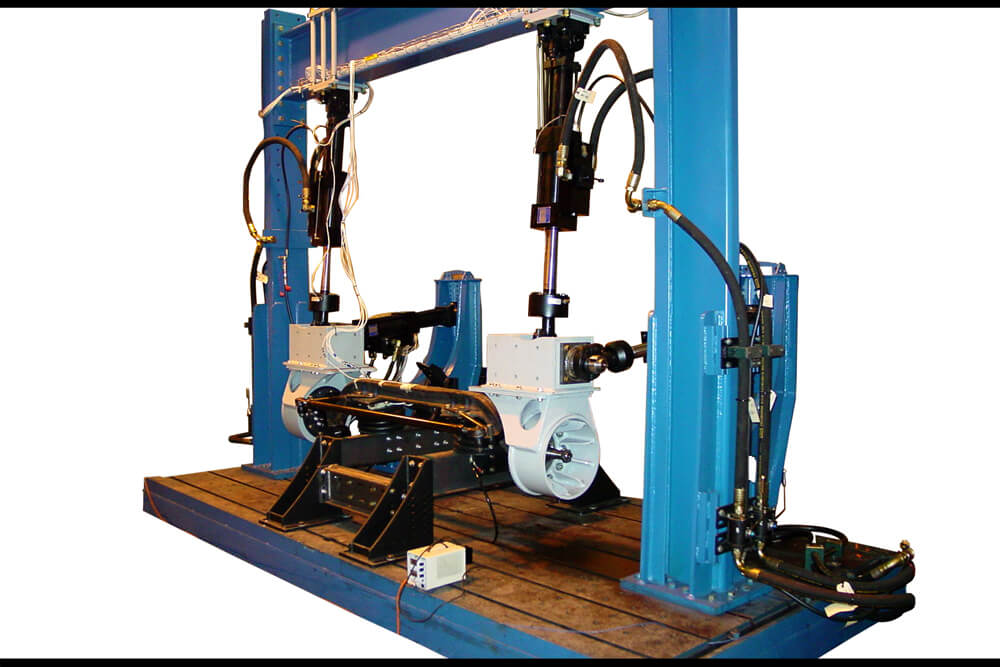

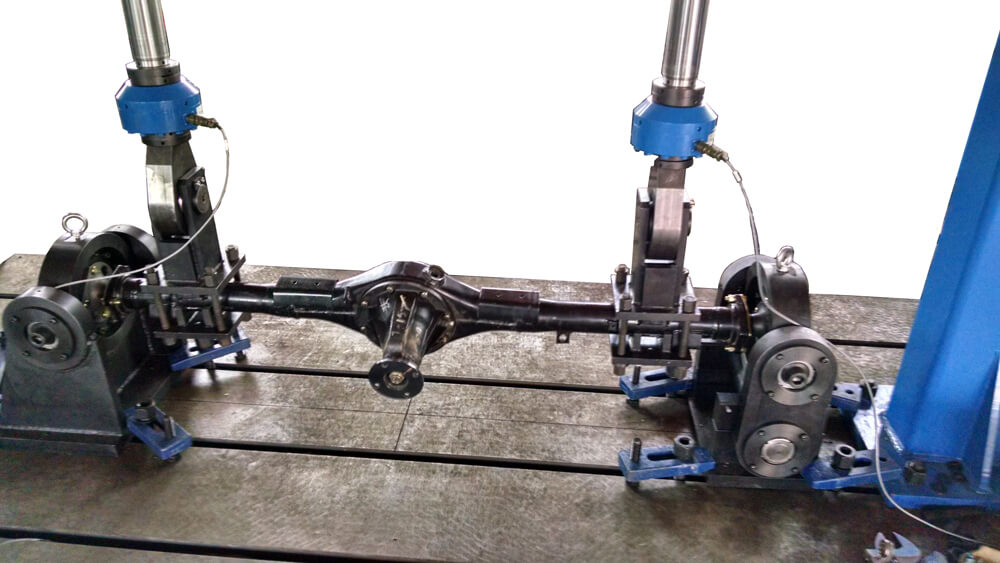

Axle Test Rig

Overview

The Axle test rig is an example of LINK’s advanced control capability. Standard fatigue rated actuators have a relatively soft piston rod that is chrome plated. The chrome plating has a surface hardness of 58-62 Rockwell C. High frequency applications often wear the chrome out quickly, because the base material is too soft. Working with advanced seal manufacturers to develop stringent surface fish requirements that will allow the use of harder surface finishes (70-74 Rockwell C for the black coating, and 86-90 Rockwell C for the tungsten carbide coating). These finishes, combined with the harder materials and Teflon seals, result in an actuator that has an extremely long life.

Key Features

- Two 35 Kip Actuators

- Two 28 Kip Actuators

- 75GPM hydraulic power unit

- Two 80 GPM control manifolds

- 4 channels of closed loop control

- 12 channels of data acquisition

Control System

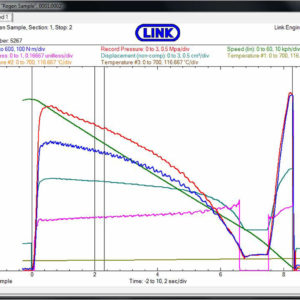

This 4-channel real time digital control system has the following capabilities:

- Block cycle programming

- Iteration to compensate for a non-linear transfer function

- Play-back of RPC® and OTF® files

- 12 additional channels of strain-gage data acquisition

- Full rig control with integrated HPS and HCM

- Amplitude control

Applications

- Block programming and real-time testing