Equipment

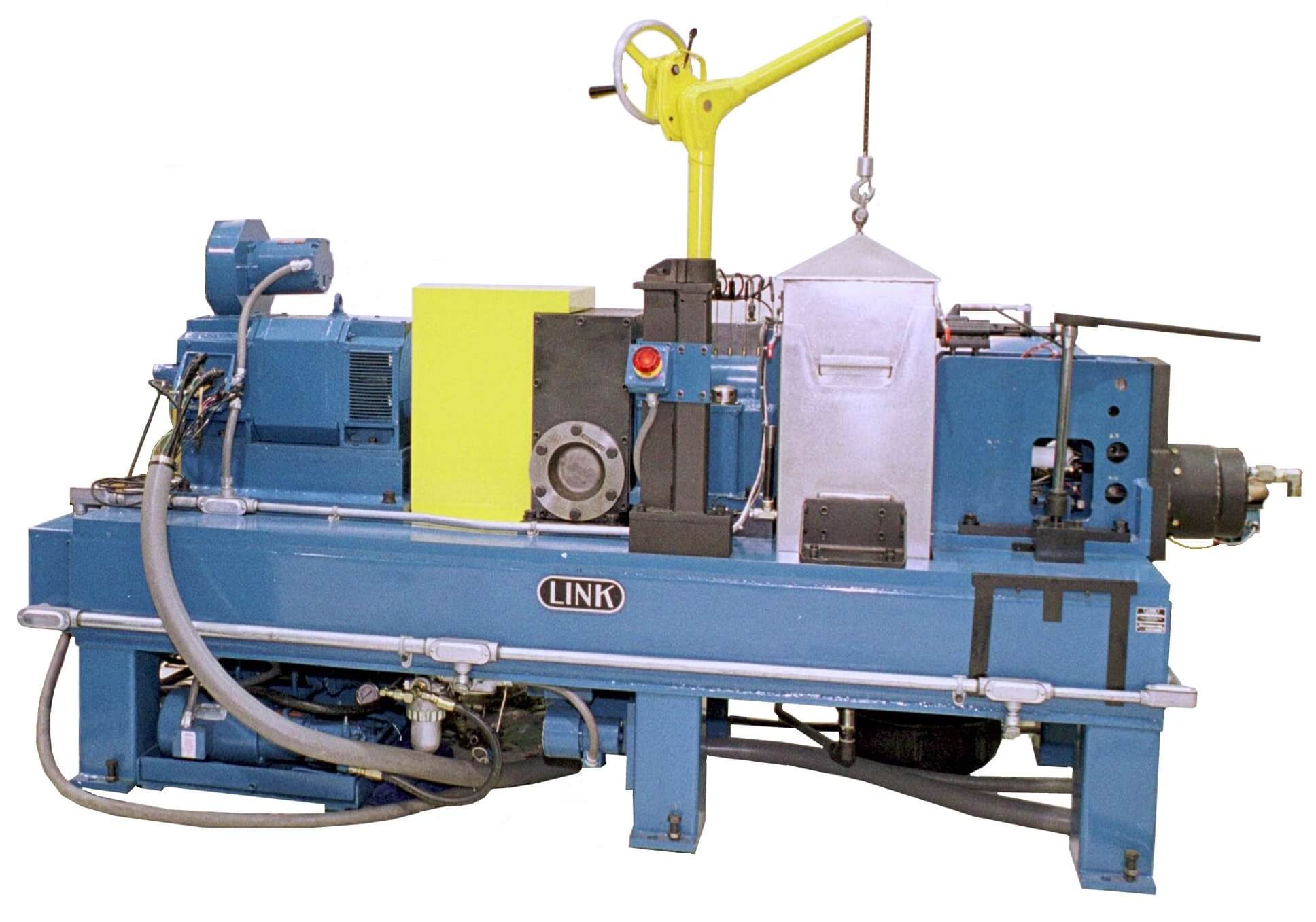

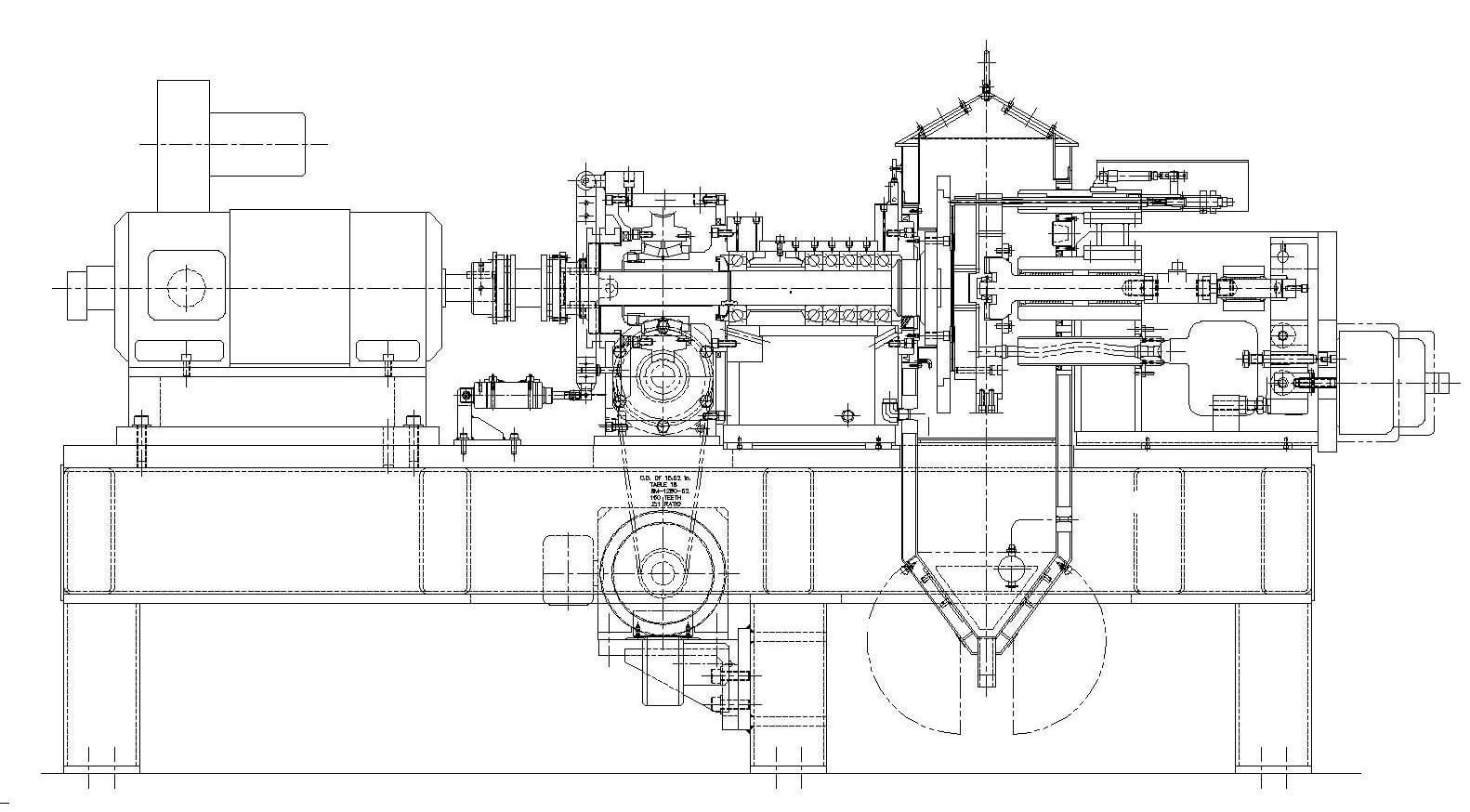

Model 1158 TO-4 Wet Friction Test Machine

Overview

The Model 1158 T0-4 Test Machine (Model 1158) conducts tests for performance and durability of wet friction clutch plates, spacer plates and transmission fluids. This incremental inertia dynamometer uses the kinetic energy of the rotating mass that is absorbed by the reaction of a rotating friction disc and an opposing stationary steel plate. The operator can select test parameters and control modes, while displaying pertinent data and monitoring test data.

The Model 1158 uses the vehicle’s drive train lubricants as the cooling medium. Apply pressures are modulated to obtain controlled outputs in repetitive tests. The control system is housed in a freestanding console and features a computer for control, data acquisition and graphic report generation. The ProLINK software system features manual and fully-automatic operation. In the automatic mode, entire test sequences may be executed without operator invention. Test procedures and test results are stored for access by the test engineer.

Key Benefits

- Performs industry standard tests to certify transmission fluid

- Latest technology software and controls

- Proven components with low maintenance

- Ease of installation (no concrete foundation required)

- Safety interlocks on all guard doors

- Fold-away chamber for ease of technician test part setup In-line reaction torque sensor

- Test fixture

- Compact workstation

- Calibration fixture for torque

Key Features

- Tabular step-by-step test script generation

- Customizable graphical data review software (RevDataPlus) for brake engineers

- Automated reporting tools through MS-Excel

- Servo controlled pneumatic force application

- Continuous slip static torque capability

- Overhead lift to assist in removal of the top cover on the test box

- Precision sensors measure shaft speed, torque, force, fluid flow and temperature