Equipment

Rotary Vibration Resonance Machine

Overview

This self-contained test machine is designed to run a variety of tests on rotary specimens. Tests such as Sine-Sweep Tests, Resonant frequency dwell and tracking, as well as optional software modules.

Key Benefits

This machine is completely self-contained and utilizes quiet hydraulics technology by using an oil cooled electric motor that provides low noise levels and has the added benefit of being available for user inspection and maintenance. Other low noise technologies have proven to be a challenge to maintain.

Another advantage of the self-contained system; the flow noise from servo-valves and hoses is contained within the sound enclosure. This reduces the overall noise level far below competitive systems where servo valves and flow noise are exposed to the operator.

A voice coil servo valve is used for control and is coupled with a short-stroke rotary actuator. The benefit of the short-stroke actuator is the reduced oil column increases the natural frequency of the hydraulic system so you test the natural frequency of the specimen and not the machine. The rotary actuator uses hydrostatic bearings for low friction and extended life, and has exceptional axial load capabilities.

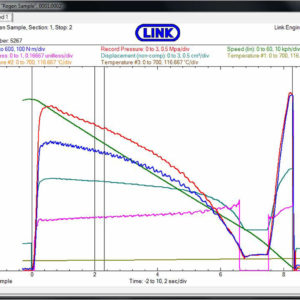

A two-channel vibration research controller runs this machine with acceleration feedbacks for control and monitoring the magnification factor at resonance frequency. The magnification factor is a function of the inertia relation and the damper material stiffness. © 2013

Application

- For durability and resonance testing of dual mass flywheel dampers